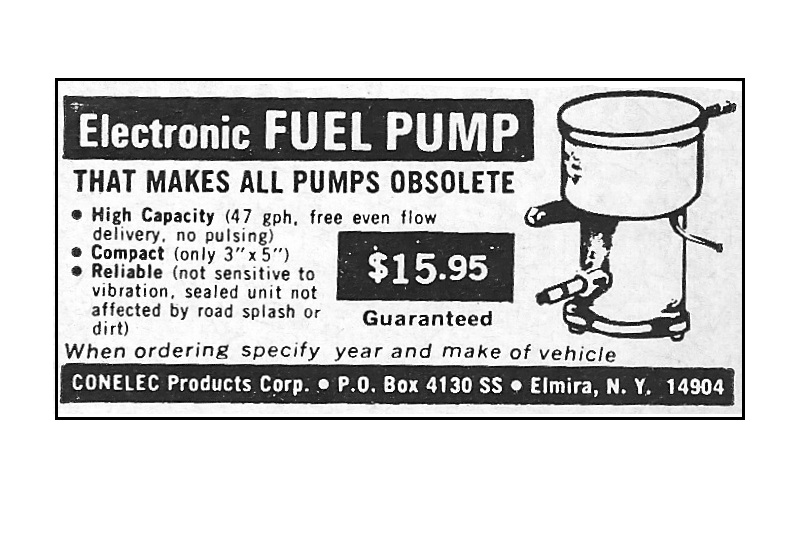

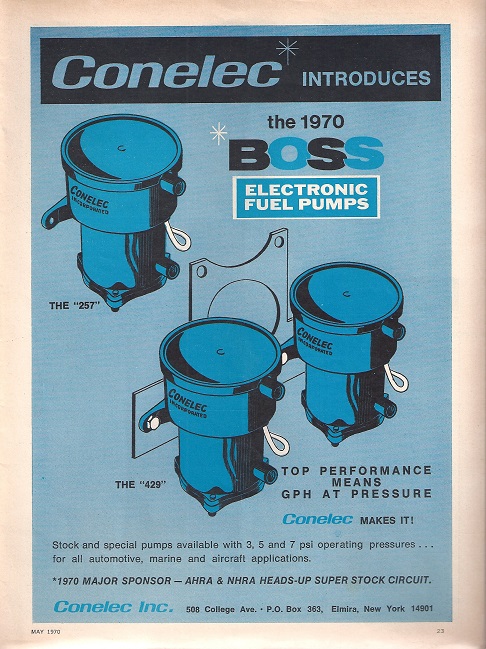

Conelec's fuel pumps were popular with drag racers.

These original Conelec fuel pumps still work like new.

This picture was taken at Long's home. The car was a gold fastback and is most likely Serial Number 41.

This is a vintage picture of the California Special prototype that was equipped with the Conelec EFI system. The car is called "the Green Hornet". David Long remembers the car.

The picture is courtesy of the Shelby American Automobile Club files.

This 1969 Shelby (Serial Number 9F02M480657) was extensively tested and was found to be very reliable. The badge on the side says "Conelec". The picture was taken in New York at Long's airplane hanger.

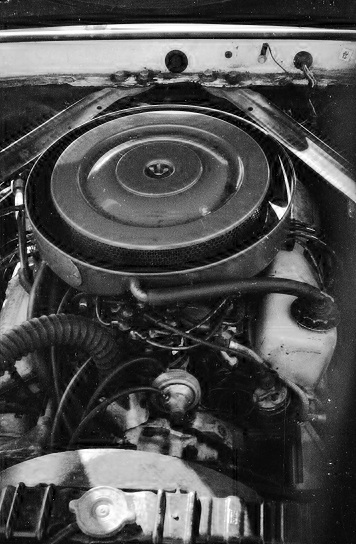

This 1970 engine is one of the first 351 Cleveland engines produced. Long tells me Ford had a small fortune in the development of the new engine. They were eager to see what the Conelec system would do for fuel

economy and emissions. The Conelec system improved both. This engine was installed in a 1969 Shelby by Conelec.

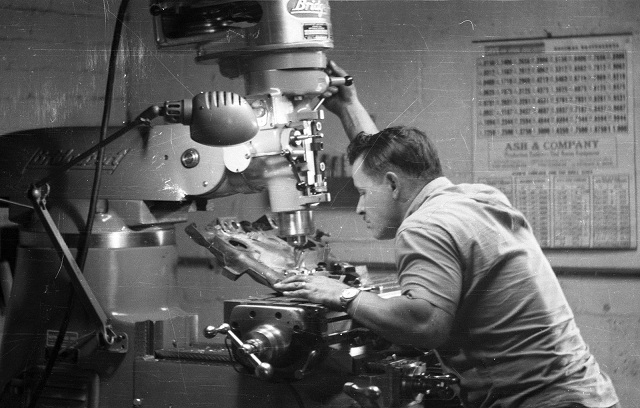

Here a Cal Long, David's brother, prepares an intake manifold to receive the injectors.

The Legacy Plan

Long was briefly able to attend SAAC 37. Here he poses with a car in the show field.

Long inspects #1088 and pronounces it fit for the conversion to EFI. He would later say the fuel rail plumbing was better than anything his good friend, Fred Goodell, ever did.

This 1969 C90X manifold was sectioned so the fuel injector ports could be properly positioned. The Conelec system uses a "transducer" (not an injector).

Here is manifold that will be used on the car. You can see every runner has a fuel injection port carefully located in the correct spot.

The center has also been milled out and the heat passages on the bottom have been blocked off. If there is one thing EFI likes it is plenty of cold air.

These aluminum hockey pucks are actually "accumulators". They were machined from original blueprints drawn by Long. Each accumulator has a special, diaphragm that

keeps the pressure constant inside the fuel rails.

Chris Long was instrumental in the assembly of the system. He had experience with the vintage Conelec system and his education as an electrical engineer was invaluable.

The accumulators are mounted on the rear of the intake at the end of each fuel rail.

Paul Fix, from Classic Tube in Lancaster, New York created a return line for the EFI system. He manufactured a steel line that is a mirror image of the supply fuel line. This line returns unused fuel to the tank.

This is not an expresso machine! This is a high pressure fuel pump called the "pumpulator". Originally, it was designed to be mounted in the wheel well of the car. For the purposes of testing and evaluation

this one is mounted inside the engine bay. This is the only known pumpulator to survive.

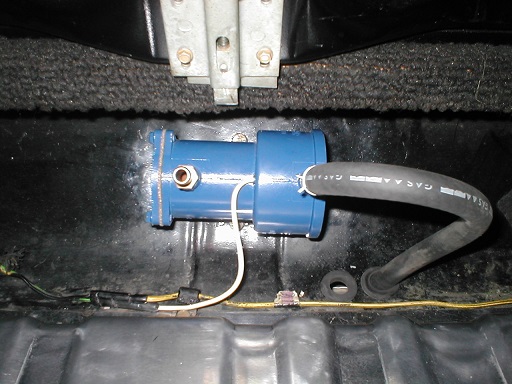

This is the low pressure fuel pump. It sends fuel to the front of the car. Mounting this pump can be a challenge with the dual exhaust system used on the Shelbys. This one is mounted in the trunk and is wired directly into the Ford wiring.

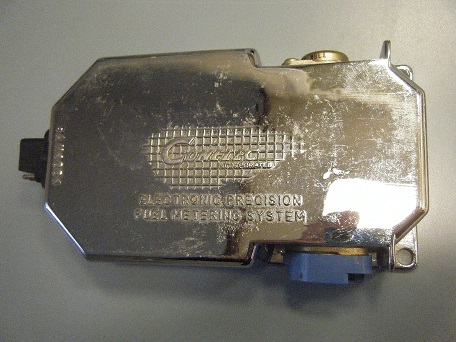

This is the brain of the EFI system. This computer is what really makes the Conelec system unique. Imagine a computer in the 1969 Shelby.

All remaining computers have been secured at Coralsnake World Headquarters along with the original blueprints.

A reproduction of the EFI wiring harness is being built by Alloy Metal Products. They are an OEM supplier to Ford and still make quality reproduction wiring today.

Unfortunately, the fuel injection harness was custom in 1968, so finding the original connectors was nearly impossible. Special molds are being built for the connector plugs.

The installation took three days. David and Chris Long worked long hours. After a few set backs and some fine tuning the machine roared to life. The first order of business was to get David Long a ride. Chris Long got the second test drive.